A Comprehensive Guide to Rebuilding Your Car's Transmission

Ever found yourself staring at a puddle of transmission fluid, the gears grinding in protest, and a repair bill that rivals the cost of your car? The thought of a transmission rebuild can be daunting, a mechanical Everest best left to the pros. But what if you could conquer that Everest yourself, saving a ton of money and gaining a serious sense of accomplishment?

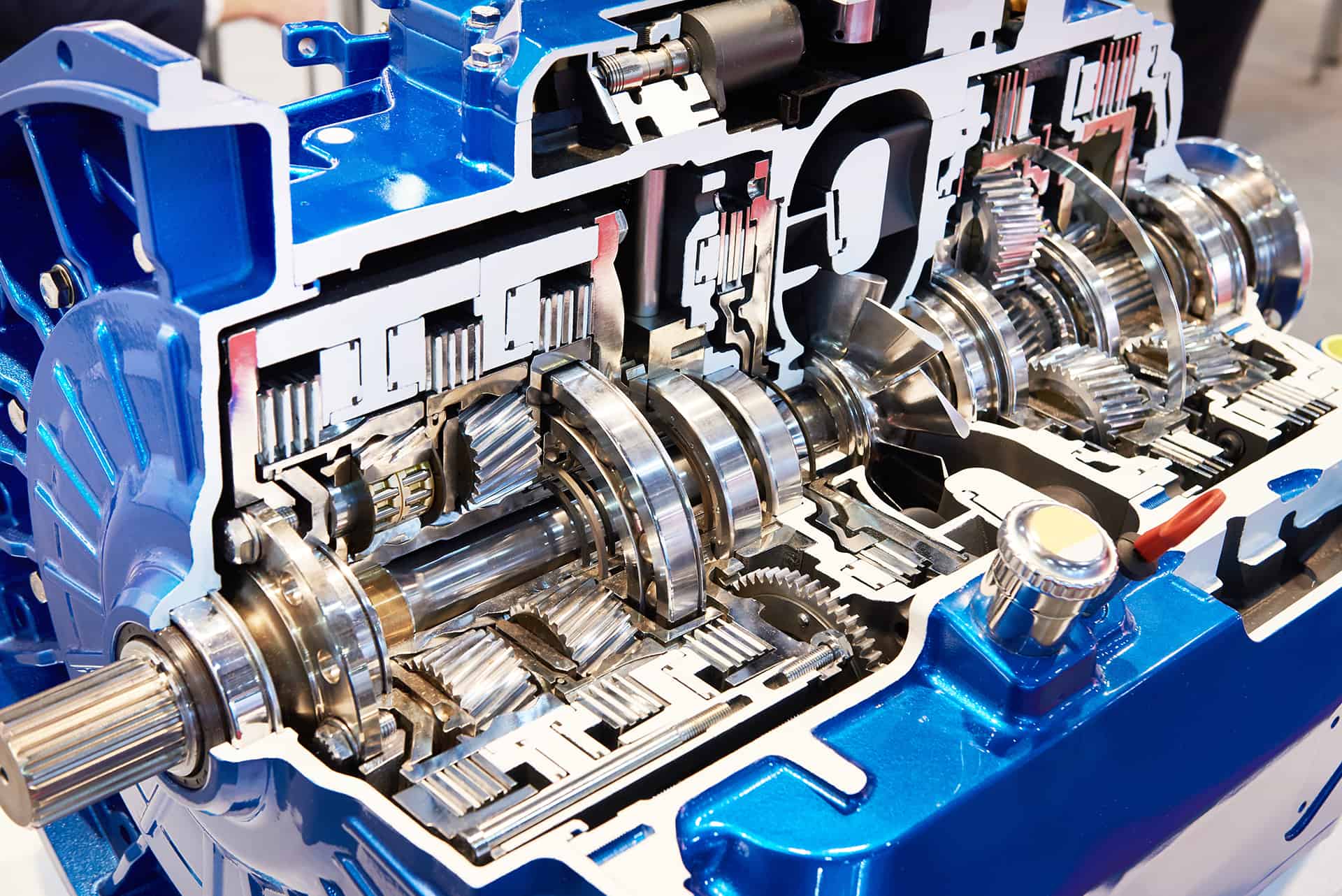

Let's face it, the prospect of taking apart your car's transmission isn't exactly a walk in the park. The intricate components, the specialized tools, the sheer complexity of it all can feel overwhelming. Many car owners are afraid to touch their transmission, fearing they'll make the problem worse and end up with an even bigger repair bill. Finding clear, reliable information can also be a challenge, with conflicting advice and confusing jargon adding to the frustration.

This guide is designed to empower you with the knowledge and confidence to rebuild your car's transmission. We'll break down the process into manageable steps, explain the terminology in plain English, and provide helpful tips and tricks along the way. Whether you're a seasoned DIY enthusiast or a complete novice, this guide will help you tackle this challenging but rewarding project.

In this comprehensive guide, we'll cover everything from diagnosing transmission problems and gathering the necessary tools, to disassembling, inspecting, and reassembling your transmission. We'll delve into the intricacies of valve bodies, clutch packs, and torque converters, offering detailed explanations and step-by-step instructions. By the end of this guide, you'll have a solid understanding of how transmissions work and the skills to rebuild one yourself, saving you money and keeping your car running smoothly. We'll be discussing topics such as transmission repair, auto mechanics, DIY car repair, transmission rebuild cost, and automatic transmission.

Understanding Transmission Types

The goal here is to help you identify the specific type of transmission in your vehicle, as the rebuild process can vary significantly between different types. We aim to provide a clear overview of the common transmission types, their characteristics, and the specific considerations for each during a rebuild.

I remember the first time I even looked under the hood of my car; it was an old beat up pickup truck that my grandpa left me when he passed away. I was terrified, and honestly, a little intimidated, but I really wanted to learn about vehicles and how they work, starting with the transmission. I remember doing a bunch of research and I noticed it was an automatic transmission. If I had known anything about cars, I would have known it was an automatic transmission, as it was a standard for cars back in the 90s, and also my grandpa was not very mechanically inclined.

Understanding the different transmission types is crucial for a successful rebuild. Automatic transmissions, for example, rely on fluid pressure to engage gears, while manual transmissions use a clutch and gears directly. Continuously Variable Transmissions (CVTs) offer a seamless gear ratio adjustment but have unique rebuild procedures. Knowing the type of transmission you're working with will dictate the specific parts you need, the tools required, and the steps involved in the rebuild process. Ignoring this fundamental aspect can lead to costly mistakes and a failed rebuild. Take the time to properly identify your transmission type before diving in to ensure a smoother and more efficient rebuild experience. This also includes researching online using your VIN number. It's also advisable to speak with a dealership.

Essential Tools and Equipment

This section focuses on outlining the necessary tools and equipment for a successful transmission rebuild. It aims to provide a comprehensive list, explain the purpose of each tool, and offer recommendations for quality and affordability.

Rebuilding a transmission requires more than just a wrench and a screwdriver. You'll need a specific set of tools to disassemble, inspect, and reassemble the intricate components. A transmission jack is essential for safely removing and installing the transmission. A set of specialized snap ring pliers will make removing and installing snap rings much easier. You'll also need a torque wrench to ensure that all bolts are tightened to the correct specifications. Other essential tools include a parts washer, a dial indicator, and a set of precision measuring tools like micrometers and calipers. Investing in quality tools will not only make the rebuild process easier but also ensure a more reliable and long-lasting repair. Don't skimp on tools – they are an investment in your project's success. It's also a good idea to get an organized container, and to label everything so that you do not forget what goes where. Most transmissions look extremely similar.

Common Transmission Problems

This part will center around identifying common transmission problems and their underlying causes. We seek to provide a clear understanding of the symptoms, diagnostic techniques, and potential solutions for various transmission issues.

Transmission problems can manifest in a variety of ways, from slipping gears and harsh shifting to delayed engagement and complete failure. Slipping gears often indicate worn clutch packs or low fluid pressure. Harsh shifting can be caused by a malfunctioning valve body or worn synchronizers in manual transmissions. Delayed engagement, where the transmission takes a while to engage after shifting into gear, can be a sign of low fluid level or internal leaks. Identifying the specific symptoms and understanding their potential causes is crucial for accurate diagnosis and effective repair. Before embarking on a full rebuild, consider simpler solutions like a fluid change or filter replacement. Sometimes, a simple maintenance task can resolve minor transmission issues. It's also always advisable to confirm that your transmission is the reason behind a problem, as often people will think it's the transmission, when it's actually the axel.

Step-by-Step Disassembly Guide

This section provides a detailed, step-by-step guide on disassembling a transmission. The intention is to offer clear instructions, visual aids, and safety precautions for each step of the process. It's crucial to have your safety goggles on, as well as gloves to protect yourself from the greasy components that you will be handling.

Disassembling a transmission requires a systematic approach and meticulous attention to detail. Start by draining the transmission fluid and thoroughly cleaning the exterior of the transmission case. Next, remove the external components, such as the torque converter (for automatic transmissions), the bellhousing, and any sensors or solenoids. Carefully document the location of each component and take pictures as you go. This will be invaluable during reassembly. Once the external components are removed, you can begin disassembling the internal components, such as the valve body, the clutch packs, and the gear train. Work in a clean and organized environment to prevent contamination and ensure that all parts are properly stored and labeled. Follow the steps outlined in this guide carefully and refer to a service manual for specific instructions related to your transmission model. I also would recommend having a friend who may know more about cars with you as you are disassembling. The service manual should provide a detailed instruction on your transmission model and may also provide illustrations.

Inspecting and Replacing Parts

This section will explore the process of inspecting transmission parts for wear and damage, and determining which parts need to be replaced. It seeks to equip readers with the knowledge to assess the condition of various components and make informed decisions about replacement.

After disassembling the transmission, thoroughly inspect each component for wear, damage, or deterioration. Clutch packs should be inspected for excessive wear or burning. Gears should be examined for chipped teeth or pitting. Bearings should be checked for play or roughness. Seals and gaskets should be inspected for cracks or leaks. Replace any parts that show signs of wear or damage. It's also a good idea to replace all seals and gaskets, even if they appear to be in good condition. This will help prevent future leaks. When replacing parts, use high-quality components from reputable manufacturers. Avoid using cheap, aftermarket parts, as they may not meet the original equipment specifications and could compromise the performance and reliability of your transmission. A very important note is that all OEM parts will cost more, so it is important to weigh the cost vs the reliability of after market parts. This is especially important to note if this will be your daily driver.

Reassembly: Putting It All Back Together

The aim of this portion of this guide is to offer a clear, step-by-step guide on reassembling a transmission, ensuring proper alignment, torque specifications, and installation of all components.

Reassembling a transmission is the reverse of disassembly, but it requires even more attention to detail. Start by lubricating all internal components with transmission fluid. Install the clutch packs, gears, and bearings in the correct order, following the instructions in the service manual. Pay close attention to the alignment of the gears and shafts. Install the valve body and torque converter (for automatic transmissions), ensuring that all bolts are tightened to the correct torque specifications. Use a torque wrench to prevent over-tightening, which could damage the transmission case or components. Finally, install the external components, such as the bellhousing and sensors. Double-check all connections and ensure that all parts are properly installed. Take your time and be patient. Rushing the reassembly process can lead to mistakes that could compromise the performance and reliability of your transmission. I would recommend having the service manual open for the specific steps for reassembly to make sure that you are not skipping any steps, or doing anything out of order.

Troubleshooting After the Rebuild

This section will focus on addressing common issues that may arise after a transmission rebuild, providing diagnostic techniques and solutions to ensure proper functioning.

Even with the most careful rebuild, problems can still occur after reinstallation. Common issues include slipping gears, harsh shifting, leaks, and unusual noises. Slipping gears may indicate low fluid level, incorrect clutch pack clearance, or a malfunctioning valve body. Harsh shifting can be caused by improper valve body calibration or worn synchronizers in manual transmissions. Leaks should be addressed immediately to prevent damage to the transmission. Unusual noises can indicate damaged bearings, gears, or other internal components. If you encounter any problems after the rebuild, consult a service manual or seek advice from a qualified mechanic. Don't ignore the symptoms, as they could lead to more serious damage. And as always, it is important to first check the basics, before checking the most complicated of steps.

Fluid Selection and Fill Procedure

The goal of this section is to guide readers in selecting the correct transmission fluid for their vehicle and performing the proper fill procedure to ensure optimal performance and longevity.

Selecting the correct transmission fluid is crucial for the performance and longevity of your transmission. Use the fluid specified in your vehicle's owner's manual or a reputable parts supplier. Different transmission types require different fluids, so be sure to use the correct one. The fill procedure also varies depending on the transmission type. Some transmissions have a dipstick, while others require a specific fill procedure using a fill plug. Follow the instructions in the service manual carefully to ensure that the fluid level is correct. Overfilling or underfilling the transmission can cause damage. Check the fluid level regularly and add fluid as needed to maintain the correct level. It's also a good idea to change the transmission fluid and filter regularly, as recommended by the manufacturer. Doing so will help keep your transmission running smoothly and prevent premature wear.

Fun Facts About Transmissions

This segment offers a collection of intriguing and entertaining facts about transmissions, providing a lighthearted break from the technical aspects of rebuilding.

Did you know that the first automatic transmission was invented in 1921 by Alfred Horner Munro? It was initially designed for use in military vehicles during World War I. The term "transmission" comes from the Latin word "transmittere," which means "to send across." The transmission is responsible for transmitting power from the engine to the wheels. Some modern transmissions have as many as ten gears, allowing for smoother acceleration and better fuel economy. The torque converter in an automatic transmission is a type of fluid coupling that allows the engine to continue running even when the wheels are stopped. Transmissions are complex and fascinating pieces of machinery, and understanding how they work can help you appreciate the engineering that goes into them. It's also a good idea to note that manual transmissions are becoming rarer and rarer.

How to Avoid Common Mistakes

This section aims to highlight common mistakes made during a transmission rebuild and offer practical tips on how to avoid them, ensuring a successful outcome.

Rebuilding a transmission can be challenging, and it's easy to make mistakes if you're not careful. One of the most common mistakes is failing to properly clean and inspect all parts. Dirt and debris can damage the transmission, and worn or damaged parts should be replaced. Another common mistake is failing to follow the torque specifications when reassembling the transmission. Over-tightening bolts can damage the transmission case or components, while under-tightening can cause leaks or other problems. It's also important to use the correct transmission fluid and fill procedure. Using the wrong fluid or overfilling or underfilling the transmission can cause damage. Finally, don't rush the rebuild process. Take your time and be patient. Rushing can lead to mistakes that could compromise the performance and reliability of your transmission. Another common issue is simply not taking pictures and keeping things organized.

What If Something Goes Wrong?

This portion addresses potential setbacks during a transmission rebuild, providing troubleshooting tips and advice on when to seek professional assistance.

Even with careful planning and execution, things can still go wrong during a transmission rebuild. If you encounter a problem that you can't resolve, don't be afraid to seek help from a qualified mechanic. Sometimes, it's better to admit defeat and let a professional handle the problem rather than risk further damage to the transmission. Before seeking professional help, try to troubleshoot the problem yourself. Consult a service manual, search online forums, or ask for advice from other DIYers. You may be able to resolve the problem with a simple fix. However, if you're not comfortable working on the transmission or if the problem is beyond your skill level, it's best to seek professional assistance. It's also important to know when to get a new transmission altogether, as often getting a brand new transmission is cheaper than having someone work on it.

Top 5 Benefits of Rebuilding Your Transmission

This section offers a list of the top 5 benefits of rebuilding your transmission, highlighting the advantages over replacement or professional repair.

Here are the top 5 benefits of rebuilding your transmission:

- Cost savings: Rebuilding your transmission can save you a significant amount of money compared to replacing it with a new or remanufactured unit.

- Customization: Rebuilding allows you to customize your transmission to suit your specific needs and preferences.

- Knowledge: You'll gain a deeper understanding of how transmissions work.

- Satisfaction: The satisfaction of knowing that you rebuilt your own transmission is priceless.

- Potentially longer lifespan: If done correctly, a rebuilt transmission can last longer than a new or remanufactured unit.

Question and Answer About Rebuilding Your Car's Transmission

Here are some common questions regarding rebuilding a car's transmission.

Question 1: Is it really possible for someone with limited mechanical experience to rebuild a transmission?

Answer: Absolutely, with the right tools, resources, and a willingness to learn, even someone with limited experience can tackle a transmission rebuild. This guide provides a step-by-step approach, breaking down the process into manageable tasks.

Question 2: How much money can I realistically save by rebuilding my transmission myself?

Answer: The savings can be substantial. A professional transmission rebuild can easily cost several thousand dollars, while rebuilding it yourself might only cost a few hundred dollars for parts and tools. The exact amount will depend on the make and model of your vehicle and the extent of the damage.

Question 3: What are the biggest risks involved in rebuilding a transmission?

Answer: The biggest risks include improper assembly, using the wrong parts, and failing to follow torque specifications. These mistakes can lead to further damage to the transmission or even complete failure. That's why it's crucial to follow this guide carefully and consult a service manual for your specific vehicle.

Question 4: How long does it typically take to rebuild a transmission?

Answer: The time required can vary depending on your experience level and the complexity of the transmission. A first-timer might spend several days or even a week rebuilding a transmission, while an experienced mechanic might be able to do it in a day or two. Be patient and don't rush the process.

Conclusion of A Comprehensive Guide to Rebuilding Your Car's Transmission

Rebuilding your car's transmission is a challenging but rewarding project that can save you a significant amount of money. By following the steps outlined in this comprehensive guide, you can gain the knowledge and confidence to tackle this task yourself. Remember to take your time, be patient, and always consult a service manual for specific instructions related to your transmission model. With careful planning and execution, you can rebuild your transmission and keep your car running smoothly for years to come.

Post a Comment for "A Comprehensive Guide to Rebuilding Your Car's Transmission"