The Basics of Internal Combustion Engines: How They Work

Ever wondered what’s really going on under the hood of your car? It's not magic, but a carefully orchestrated dance of physics and engineering. Let's crack open the engine and see what makes it tick!

For many, the inner workings of an engine can feel like a daunting mystery. The complex terminology, the seemingly endless array of parts, and the sheer power contained within a relatively small space can leave you feeling lost and confused.

This article aims to demystify the internal combustion engine (ICE). We'll explore the fundamental principles that govern its operation, break down the four-stroke cycle that forms its heart, and illuminate the critical components that work together to transform fuel into motion.

By understanding the basics of how internal combustion engines function – from the intake of air and fuel to the expulsion of exhaust gases – you'll gain a newfound appreciation for the engineering marvel that powers most vehicles on the road today. We'll cover topics like the four-stroke cycle, key engine components, fuel and ignition systems, and even touch upon alternative engine designs. Let's dive in!

The Four-Stroke Cycle: The Engine's Heartbeat

The target of this section is to break down the four key phases of the engine's operation – Intake, Compression, Combustion (or Power), and Exhaust – into easily digestible explanations. It aims to illustrate how these phases work in sequence to create a continuous cycle of energy production.

I remember when I first started learning about engines, the four-stroke cycle seemed like an abstract concept. I’d read the definitions, but it didn't truly click until I saw an animation that visually demonstrated each stroke. That's when the "aha!" moment hit.

The four-stroke cycle is the foundation of most internal combustion engines found in cars, motorcycles, and even some lawnmowers. It’s a sequence of events that repeats continuously to convert fuel into mechanical energy. Let's break down each stroke:

- Intake: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing a mixture of air and fuel (or just air in a diesel engine) to be drawn into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. This increases the temperature and pressure, making the mixture more volatile and ready for combustion.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture (in a gasoline engine). In a diesel engine, the compressed air is so hot that the fuel ignites spontaneously when injected. The resulting explosion forces the piston down, providing the power that turns the crankshaft.

- Exhaust: The exhaust valve opens as the piston moves back up, pushing the burnt gases out of the cylinder and into the exhaust system.

This cycle repeats continuously, providing the engine with the power it needs to operate. The precise timing and coordination of these strokes are crucial for efficient engine performance. Understanding the four-stroke cycle is essential for grasping the fundamental principles of internal combustion engines.

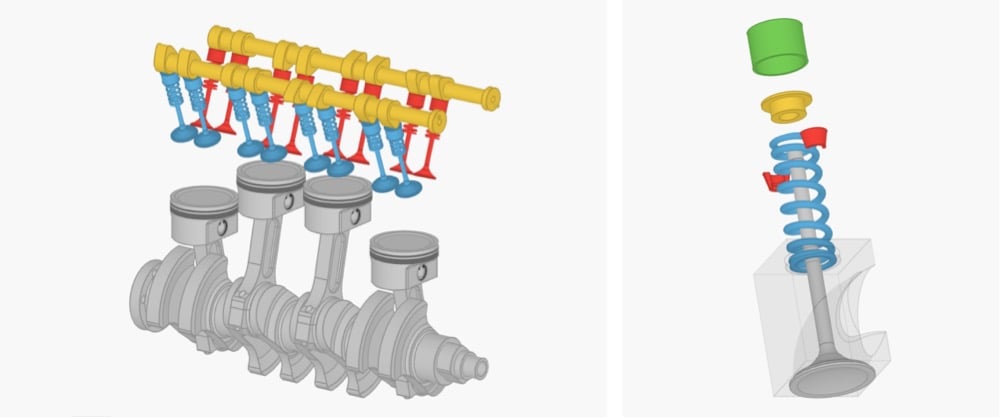

Key Engine Components: The Players in the Game

The target of this section is to identify and describe the major physical components of an engine, such as the pistons, cylinders, crankshaft, connecting rods, valves, and camshaft. It explains their individual roles and how they interact to facilitate the four-stroke cycle.

The internal combustion engine is a complex machine comprised of many interconnected parts. Let's explore some of the key players:

- Piston: A cylindrical component that moves up and down within the cylinder, driven by the force of combustion and connected to the crankshaft.

- Cylinder: The chamber within which the piston moves. The engine's cylinders are typically arranged in a line (inline engine) or in a "V" shape (V-engine).

- Crankshaft: A rotating shaft that converts the linear motion of the pistons into rotary motion, which is then transmitted to the wheels.

- Connecting Rod: Connects the piston to the crankshaft, transferring the force of the piston's movement.

- Valves: Control the flow of air and fuel into the cylinder (intake valve) and the expulsion of exhaust gases (exhaust valve).

- Camshaft: A rotating shaft with lobes (cams) that open and close the valves at the correct times.

- Spark Plug: In gasoline engines, the spark plug ignites the air-fuel mixture, initiating the combustion process.

These components work in precise coordination to ensure the smooth and efficient operation of the engine. The design and materials used in these parts are critical for withstanding the high temperatures, pressures, and stresses involved in the combustion process. Understanding these components is crucial for understanding how the engine functions.

History and Evolution: From Steam to Spark

The target of this section is to provide a brief historical overview of the development of internal combustion engines, from their early experimental beginnings to the sophisticated designs of today. It touches on the key milestones and innovations that shaped the modern ICE.

The story of the internal combustion engine is a fascinating journey of innovation and refinement. While the concept of using combustion to generate power dates back centuries, it was the 19th century that saw the first practical ICEs emerge.

Early engines were bulky, inefficient, and often unreliable. However, pioneers like Étienne Lenoir, Nikolaus Otto, and Rudolf Diesel made significant contributions that paved the way for the modern engine. Otto's four-stroke engine design proved to be a breakthrough, laying the foundation for the vast majority of engines used today. Diesel's invention of the diesel engine, which relies on compression ignition rather than spark ignition, offered greater efficiency and power.

Over the years, countless improvements have been made to ICEs, including advancements in fuel injection, ignition systems, materials, and engine management. Today, engines are more powerful, efficient, and cleaner than ever before. The history of the internal combustion engine is a testament to human ingenuity and the relentless pursuit of better ways to harness energy.

Hidden Secrets: Efficiency and Optimization

The target of this section is to explore some of the less obvious aspects of engine design and operation that contribute to efficiency and performance, such as variable valve timing, turbocharging, and fuel injection strategies. It reveals how engineers optimize the engine for maximum power and fuel economy.

Beyond the basic principles of the four-stroke cycle and the core engine components, there are many sophisticated techniques used to enhance the efficiency and performance of internal combustion engines.

One such technique is variable valve timing (VVT), which allows the engine to adjust the timing and duration of valve opening based on engine speed and load. This optimizes airflow into and out of the cylinders, improving power and fuel economy.

Another key technology is turbocharging, which uses exhaust gases to drive a turbine that compresses the intake air. This increases the amount of air entering the cylinders, allowing the engine to burn more fuel and produce more power.

Modern fuel injection systems also play a crucial role in optimizing engine performance. These systems precisely meter and inject fuel into the cylinders at the optimal time and pressure, ensuring complete combustion and minimizing emissions.

These are just a few examples of the many "hidden secrets" that engineers use to optimize internal combustion engines. Continuous innovation in these areas is driving further improvements in engine efficiency, power, and emissions.

Recommendations: Maintaining Your Engine

The target of this section is to offer practical advice on how to maintain your engine properly, including regular oil changes, filter replacements, and other preventative measures. It emphasizes the importance of proper maintenance for extending engine life and ensuring optimal performance.

Regular maintenance is essential for keeping your engine running smoothly and reliably for years to come. Neglecting maintenance can lead to costly repairs and reduced engine life. Here are some key recommendations:

- Regular Oil Changes: Changing your engine oil at the recommended intervals is crucial for lubricating engine components, removing contaminants, and preventing wear.

- Filter Replacements: Replacing your air filter, fuel filter, and oil filter at the recommended intervals ensures that your engine receives clean air, fuel, and oil, preventing damage and maintaining performance.

- Coolant Flushes: Flushing your cooling system periodically removes deposits and prevents corrosion, ensuring that your engine stays cool and avoids overheating.

- Spark Plug Replacement: Replacing your spark plugs at the recommended intervals ensures proper ignition and efficient combustion.

- Regular Inspections: Regularly inspect your engine for leaks, worn belts, and other potential problems. Addressing these issues early can prevent more serious damage.

Following these recommendations can help extend the life of your engine and keep it running at its best. Consult your owner's manual for specific maintenance recommendations for your vehicle.

Alternative Engine Designs: Beyond the Four-Stroke

The target of this section is to briefly introduce alternative engine designs, such as rotary engines and opposed-piston engines, and explain how they differ from the conventional four-stroke engine. It highlights the advantages and disadvantages of these alternative designs.

While the four-stroke engine is the most common type of internal combustion engine, there are other designs that offer unique advantages.

One such design is the rotary engine, also known as the Wankel engine. This engine uses a triangular rotor that spins within a housing, creating combustion chambers that move through the four phases of the cycle. Rotary engines are known for their smooth operation, high power-to-weight ratio, and compact size. However, they can also be less fuel-efficient and produce higher emissions than four-stroke engines.

Another alternative design is the opposed-piston engine, which uses two pistons in each cylinder that move towards each other, creating a combustion chamber between them. Opposed-piston engines can offer high efficiency and low emissions, but they are more complex to manufacture and maintain.

These alternative engine designs represent ongoing efforts to improve the performance and efficiency of internal combustion engines. While they may not be as widely used as four-stroke engines, they demonstrate the diversity of engineering solutions in the pursuit of better powerplants.

Troubleshooting Common Issues: Diagnosing Engine Problems

The target of this section is to provide a basic guide to troubleshooting common engine problems, such as starting difficulties, rough idling, and loss of power. It offers simple diagnostic tips and suggests potential solutions.

Even with regular maintenance, engines can sometimes experience problems. Here are some common issues and potential solutions:

- Starting Difficulties: This could be due to a dead battery, a faulty starter motor, a clogged fuel filter, or a problem with the ignition system.

- Rough Idling: This could be caused by vacuum leaks, dirty spark plugs, a faulty idle air control valve, or a problem with the fuel injection system.

- Loss of Power: This could be due to a clogged air filter, a faulty mass airflow sensor, a clogged catalytic converter, or a problem with the fuel system.

- Overheating: This could be caused by a low coolant level, a faulty thermostat, a clogged radiator, or a leaking water pump.

These are just a few examples of the many problems that can occur with engines. If you experience any of these issues, it's important to diagnose the problem correctly before attempting any repairs. Consulting a qualified mechanic is always a good idea if you're not comfortable working on your engine yourself.

Future Trends: The Evolution Continues

The target of this section is to discuss emerging trends in engine technology, such as gasoline direct injection, cylinder deactivation, and the integration of hybrid and electric systems. It explores the future of the internal combustion engine in a world increasingly focused on sustainability.

The internal combustion engine is not standing still. Engineers are constantly working on new technologies to improve its efficiency, reduce its emissions, and integrate it with hybrid and electric systems.

One key trend is gasoline direct injection (GDI), which injects fuel directly into the combustion chamber, allowing for more precise control of the air-fuel mixture and improving fuel economy.

Another technology is cylinder deactivation, which shuts off some of the engine's cylinders under light load conditions, reducing fuel consumption.

Perhaps the most significant trend is the integration of ICEs with hybrid and electric systems. Hybrid vehicles use an electric motor to assist the engine, improving fuel economy and reducing emissions. Plug-in hybrid vehicles can be charged from an external source, allowing for even greater fuel savings and reduced emissions.

The future of the internal combustion engine is likely to involve a combination of these technologies, as well as further advancements in materials, engine management, and alternative fuels. While electric vehicles are gaining popularity, ICEs are likely to remain a significant part of the transportation landscape for many years to come.

Fun Facts: Engine Trivia

The target of this section is to share some interesting and little-known facts about engines, making the topic more engaging and entertaining.

Did you know that the first internal combustion engine was invented in 1876 by Nikolaus Otto? Or that the Bugatti Veyron's engine has 16 cylinders and four turbochargers? Here are some more fun facts about engines:

- The term "horsepower" was coined by James Watt to compare the power of steam engines to the power of horses.

- The first car to break the sound barrier was powered by a jet engine.

- Some engines use a technology called "variable compression ratio," which allows the engine to adjust its compression ratio based on driving conditions.

- The world's largest internal combustion engine is a two-stroke diesel engine used in container ships. It's over 80 feet tall and weighs over 2,300 tons.

These fun facts illustrate the incredible diversity and ingenuity of engine design. The internal combustion engine has a long and fascinating history, and it continues to evolve and surprise us.

How to Build Your Own: A Simplified Model

The target of this section is to provide instructions for building a simplified model engine, using readily available materials. This hands-on project helps to reinforce understanding of the engine's basic principles.

Building a simplified model engine can be a fun and educational project. While you won't be able to build a fully functional engine, you can create a model that demonstrates the basic principles of the four-stroke cycle.

There are many resources available online that provide instructions for building simple model engines using materials like cardboard, syringes, and balloons. These models typically use syringes to represent the cylinders and pistons, and balloons to represent the valves. By manipulating the syringes and balloons, you can simulate the intake, compression, combustion, and exhaust strokes.

While these models are not as sophisticated as real engines, they can be a valuable tool for understanding the fundamental principles of the four-stroke cycle. Building your own model engine can be a rewarding experience that deepens your understanding of how engines work.

What If: Alternative Fuels

The target of this section is to explore the potential of alternative fuels, such as biofuels, hydrogen, and synthetic fuels, to power internal combustion engines. It discusses the advantages and disadvantages of these fuels, and their potential to reduce emissions.

As the world grapples with climate change and the need to reduce emissions, alternative fuels are gaining increasing attention. These fuels offer the potential to power internal combustion engines while reducing our reliance on fossil fuels.

Biofuels, such as ethanol and biodiesel, are made from renewable sources like corn, soybeans, and vegetable oils. They can be blended with gasoline or diesel fuel, reducing emissions of greenhouse gases.

Hydrogen is another promising alternative fuel. It can be used in fuel cells to generate electricity, or it can be burned directly in internal combustion engines. Hydrogen combustion produces only water as a byproduct, making it a very clean fuel.

Synthetic fuels, also known as e-fuels, are made from carbon dioxide and hydrogen using renewable energy. They can be designed to mimic the properties of gasoline or diesel fuel, allowing them to be used in existing engines without modification.

While alternative fuels offer many advantages, they also have some challenges. Biofuels can compete with food production, hydrogen is difficult to store and transport, and synthetic fuels are currently expensive to produce. However, ongoing research and development are addressing these challenges, and alternative fuels are likely to play an increasingly important role in the future of transportation.

Listicle: 5 Amazing Engine Innovations

The target of this section is to present a list of five groundbreaking innovations in engine technology, highlighting their impact on performance, efficiency, and emissions.

Here are five amazing innovations that have transformed the internal combustion engine:

- Fuel Injection: Replacing carburetors with fuel injection systems has allowed for more precise control of the air-fuel mixture, improving fuel economy and reducing emissions.

- Turbocharging: Using exhaust gases to drive a turbine that compresses the intake air has significantly increased engine power and efficiency.

- Variable Valve Timing: Adjusting the timing and duration of valve opening based on engine speed and load has optimized airflow and improved both power and fuel economy.

- Catalytic Converters: These devices reduce harmful emissions from exhaust gases, converting pollutants into less harmful substances.

- Engine Management Systems: Computer-controlled engine management systems have optimized engine performance, fuel economy, and emissions by precisely controlling all aspects of engine operation.

These innovations have revolutionized the internal combustion engine, making it more powerful, efficient, and environmentally friendly.

Question and Answer

Q: What is the difference between a gasoline engine and a diesel engine?

A: Gasoline engines use spark plugs to ignite the air-fuel mixture, while diesel engines rely on compression ignition, where the air is compressed so much that the fuel ignites spontaneously when injected.

Q: What is the purpose of a catalytic converter?

A: A catalytic converter reduces harmful emissions from exhaust gases, converting pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances like carbon dioxide, water, and nitrogen.

Q: What is variable valve timing?

A: Variable valve timing (VVT) is a technology that allows the engine to adjust the timing and duration of valve opening based on engine speed and load, optimizing airflow into and out of the cylinders and improving power and fuel economy.

Q: How often should I change my engine oil?

A: The recommended oil change interval varies depending on the vehicle and the type of oil used. Consult your owner's manual for specific recommendations, but generally, oil changes should be performed every 3,000 to 7,500 miles.

Conclusion of The Basics of Internal Combustion Engines

In conclusion, the internal combustion engine is a marvel of engineering, transforming the chemical energy of fuel into mechanical motion. Understanding the four-stroke cycle, key components, and ongoing innovations allows us to appreciate the complexity and ingenuity behind this ubiquitous technology. While electric vehicles are emerging, the ICE continues to evolve, playing a vital role in transportation for the foreseeable future. Keep learning, keep exploring, and keep appreciating the power under the hood!

Post a Comment for "The Basics of Internal Combustion Engines: How They Work"